HOME >> PRODUCTS SERVICE >> BTER Valve >> GPR-A100/A200 Gas Pressure Regulator

FeaturesHigh capacity due to axial flow High range ability and high pressure cuts Valve sleeves are specially coated to eliminate slip stick Noise reducing outlet duct and /or internal silencer available Local position indicator standard Electric valve-position remote indicator available Simple design, purely pneumatic operation, robust Fail to close / fail to open models available Provided with a noise reducing outlet duct and /or an internal silencer Technical Data

How the regulator works

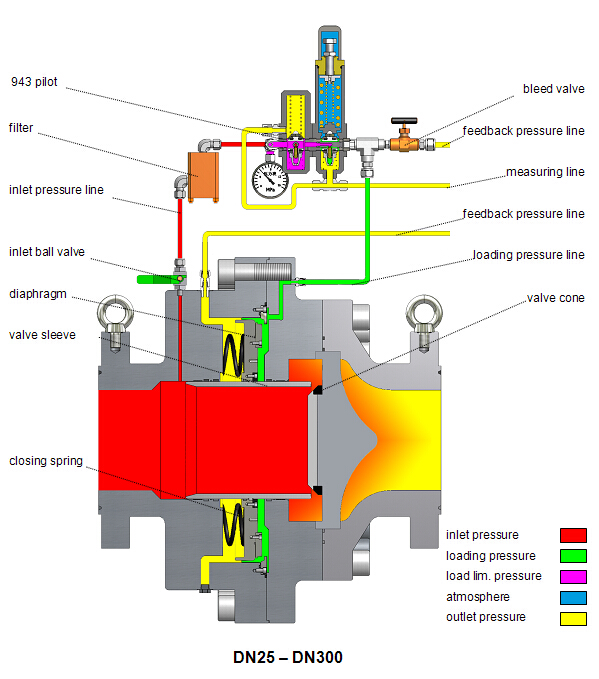

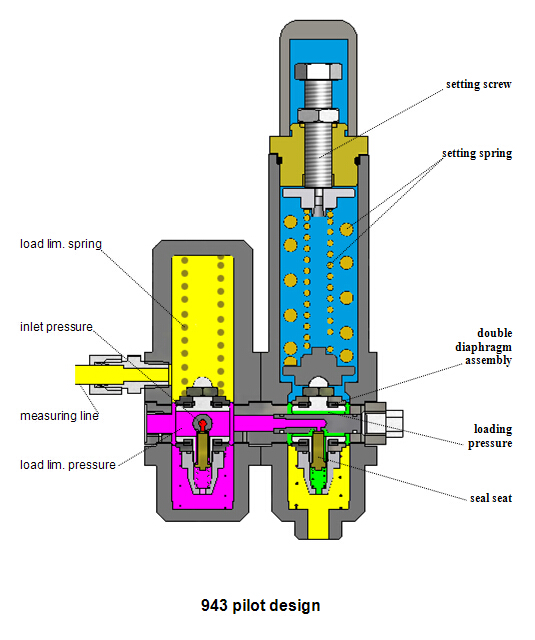

Gas pressure regulator is a pressure control device in the pressure regulating system. The Diaphragm Unit (permanently connected to the sleeve) divides the Regulator into two rooms. One of the rooms is connected to outlet pressure, and the other to loading pressure produced by the pilot according to pressure downstream. Due to lack of pressure, the regulator spring acts on the diaphragm unit and closes the sleeve. The sleeve moves to its open position when the force produced by loading pressure acting on the diaphragm unit becomes greater than the force produced by downstream regulated pressure added to the load of the regulator spring. The sleeve keep station when the two forces are equal under these conditions, downstream pressure is equal to the system’s set value. Any change in requested flow-rate produces a variation in downstream regulated pressure and the regulator controlled by the pilot opens or closes to deliver the requested flow-rate while keeping downstream pressure uniform.

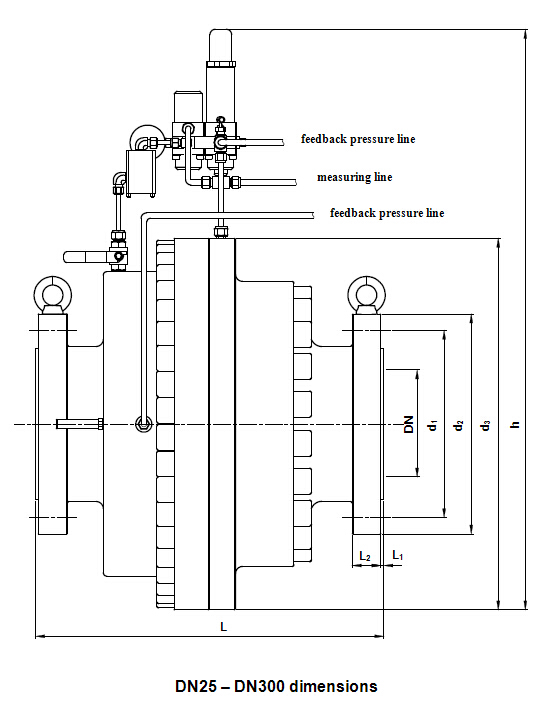

Valve Design Pilot Design Dimensions Dimensions

Connections & Pilot type

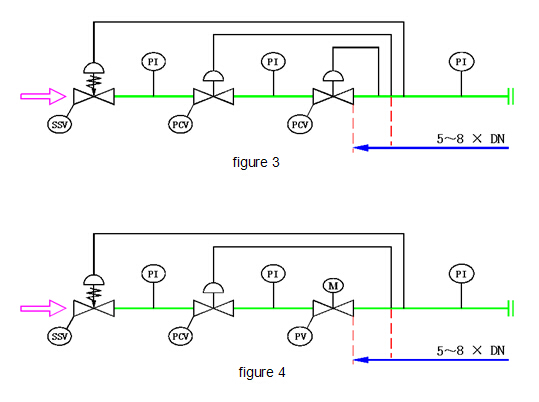

Pressure sampling point mounting position As shown in Figure 3 and 4, the gas pressure regulator (PCV) pressure sampling point is 5-8xDN from the working valve (PCV or PV) .

Order Type Selection

Type Description

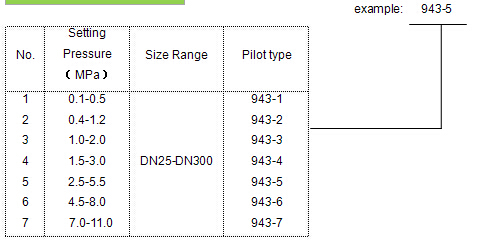

Pilot type

Other special feature

* For matching the export reducing noise reduction device and internal noise reduction device should be marked as GPR-A200b type.

|

CONTACT US

BEST ENERGY EQUIPMENT CO.,LTD. Tel:+86 22 22193891/92/93